The best safety device is a careful worker

Foreword

This Work Health & Safety Management Plan (WHSMP) is intended to assist Clarendon Homes in providing a safe place of work for its employees, staff, suppliers and subcontractors on Clarendon construction sites.

The WHSMP also outlines our Standard Control for High Risk Construction Activities and the Respirable Silica Dust Control Plan for the site.

It is an expectation of Clarendon Homes that the requirements of this WHS Management Plan is put into practice all persons on a Clarendon Homes Construction Site.

Clarendon Homes strives to provide high standards in all areas of safety and environmental management. Our company ethos "Safety is Paramount” represents the level of commitment it has to all people affected by our activities and we take this very seriously and we expect the same level of commitment from you.

Please Note: This plan must read in conjunction with the Clarendon Site Signage, site plans and our contractors site specific risk assessments as they specify the site specific details such, site emergency contact information , site specific hazards and control measures to be implemented.

Copies of the WHSMP are available in the following locations:

- QR Code located on the site safety sign

- Site Meter box

- Via Clarendon Homes HSE Contractors Induction Page

Table of Contents

Site Emergency Contacts. 3

1. Site Safety Rules. 3

2. Roles and Responsibilities. 4

3. Contractor Requirements. 5

4. Training and Competency. 5

5. Hazard & Risk Management. 6

6. WHS Communication and Consultation. 7

7. WHS Issue Resolution. 7

8. Emergency Procedures. 7

9. Incident Management. 7

10. Contactor non conformances. 8

11. Environmental Management. 9

12. Standard Controls for High Risk Construction Activities 10

13. Respirable Silica Dust Control Plan. 34

14. Choosing the right RPE. 46

Site Emergency Contacts

Clarendon Contacts

Site Manager - See the Site Safety Signage

Group HSE Manager - David Currie: 0407 150 158

Clarendon 24hr Emergency Contact Number: 0409 565 197

Emergency Contacts

Police, Fire & Ambulance: 000 or 112 (Mobile)

Division of Workplace Health and Safety QLD: 1300 369 915

Dial Before You Dig: 1100

Electricity / Gas: 13 19 62

Water: 13 74 68

Poison Information Centre: 13 11 26

Site Safety Rules

- No children are allowed on site;

- No animals (pets) are allowed on site;

- All contractors must work in accordance with their Safe Work Method Statement;

- Complete a Site Specific Risk Assessment prior to starting work on site.

- Do not dispose of any material or substance in any drains, gutters neighbouring land or waterways.

- Workers must wear correct PPE (as per work method statements, material safety data sheets or manufacturer’s recommendations) during specific work activities;

- All gates and fences must be locked and reinstated at the end of each day or when the site is unattended;

- Place rubbish in the appropriate area / facility before leaving the site each day;

- Do alter or remove sediment or erosion control barriers

- Harassment or Workplace bullying will not be tolerated and must be reported to the Site Manager , Construction Area Manager or HSE Department immediately;

- No alcohol or illegal drugs permitted on site - Any person affected by alcohol or drugs will not be tolerated and will be denied access to the site;

- Do not alter safety installations. This includes: ties , planks , signage, handrails etc.

- Electrical equipment must be inspected ,tagged and tagged at intervals not exceeding 3 months and maintained in locations where they are not likely to be damaged or create a trip hazard;

- All electrical generators must be fitted with an RCD unit;

- No piggy backing of leads or double adaptors to be used on site;

- All trades must have an applicable first aid kit.

Roles And Responsibilities

Site Manager

The WHS responsibilities of the Site Manager include:

- Perform a Pre-start risk assessment;

- Make sure the site safety signage and emergency contact information is displayed and kept up to date;

- Display the WHS management plan on site;

- Coordinate and monitor the installation of all safety systems (e.g. temporary fencing , stair voids and perimeter edge protection systems scaffolds installation, etc);

- Undertake fortnightly HSE Site Inspections;

- Identification, assessment and documentation of workplace hazards;

- Implement, monitor and review control measures resulting from the risk assessment process;

- Monitor high risk construction activities in-line the Clarendons standard controls for high risk construction activates;

- Monitor contractors work activities in line with their SWMS and Clarendon Site WHS Management Plan;

- Communicate and consult with contractors regarding any WHS issues that may have an impact on the workplace (site);

- Undertake HSE inductions for contractors and visitors as required;

- Ensure all incidents are reported in a timely manner;

- Assisting in implementing and monitoring of the site emergency response plan;

- Stop all works if any unsafe work practices are identified.

HSE Department

The WHS responsibilities of the HSE Department include:

- Develop and keep up to date the WHS Site Management Plan;

- Provide training on the implementation of the WHS management plan;

- Undertake and document audits on High Risk Construction phases of construction;

- Undertake contractors audits;

- Providing feedback on WHS performance resulting from Construction site and contractor audits;

- Issuing and following up on any corrective actions as a resulting of any non conformance that is identified;

- Stop all works if any unsafe work practices are identified;

- Investigate workplace incidents;

- Identification, assessment and documentation of workplace hazards;

- Contribute to any workplace communication and consultation.

Contractors

The WHS responsibilities of contractors include:

- Ensuring workers are inducted to the Clarendon Homes WHS requirements prior to commencement of work and comply with the site safety rules;

- Making sure all workers have been trained in the SWMS for high risk constructions activities;

- Ensuring all employees and subcontractors are adequately trained for the work they intend to undertake and all young or inexperienced workers must be adequately supervised at all times;

- Whilst at work, ensuring all work is in line with their Safe Work Method Statement (SWMS), taking all reasonable care to ensure the health and safety for themselves and others in the workplace who may be affected by their actions or omissions at work;

- Undertake a site specific Risk assessment and report any hazards to the Clarendon site Manager before commencing work on site;

- As required review the Site WHS Management Plan;

- Understanding and working to their own and our company WHS policies and procedures and legislative standards;

- Participating in the consultation process and risk management of WHS issues that are encountered onsite;

- Ensuring personal protective equipment (PPE) identified in the SWMS is readily available on site, in good condition and worn at the appropriate time;

- Ensuring that all site personnel are responsible for carrying out their works at a safe working distance from operating plant and equipment;

- Ensuring that all plant and equipment used onsite is fully maintained according to manufacturers and legislative requirements;

- Ensuring isolation, removal and or repair of any non-compliant plant or equipment;

- Ensure that all first aid equipment/resources are fully stock and maintained;

- Reporting any workplace hazards, incidents and injuries;

- Following the site emergency response plan.

Contractor Requirements

All contractors working on a Clarendon Homes construction site must meet the following mandatory requirements:

- Be rated as a compliant contractor on the Clarendon’s vendor database and maintain compliance with up to date documentation as required;

- Undertake the WHS General Induction Training for construction work;

- Review any site specific information or emergency contact information before entering site;

- Appoint a site supervisor/foreman/leading hand for each site;

- Have a current copy of their SWMS onsite – all workers working onsite must have been given adequate training and signed off on the SWMS that they understand and agree with the requirements of their employer’s SWMS;

- All electrical equipment must be tested and tagged every 3 months;

- Undertake an assessment of the site prior to commencing work;

- Have an appropriate fire fighting equipment for any hot works or the use of flammable substances;

- Maintain a copy of their hazardous chemical register onsite – all workers working with hazardous substances onsite must have been given adequate training in it’s storage and handling requirements;

- Appropriate PPE as outlined in their SWMS;

- Consult with Clarendon and your workers about safety issues.

Training And Competency

No person will carry out construction work until they have met the following minimum requirements of WHS training:

- OHS Construction Induction for Construction Work;

- Workplace or task, specific to the, including competencies and licenses, and;

- Clarendon HSE General Site Induction.

The following matrix identifies the training requirements for Clarendon construction sites.

Clarendon Homes HSE Contractor Induction

All persons wishing to perform construction work on a Clarendon Homes construction site must undertake and a Clarendon HSE Contractor Induction before commencing work on any Clarendon site. The contractor Induction can be undertaken via the Induction link that can be sent each contractor via email and can be also perform by a Clarendon Construction or HSE personnel using their iPad.

Induction of Non – English speaking personnel

All Non-English speaking tradespersons must be accompanied by someone who can adequately communicate the induction information and instructions.

Clients, Visitors & Authorised Employee Representative

If you are planning to be onsite for less than 1 day and will not be undertaking any construction work:

- You do not need to undergo the HSE Site Induction. However, you must be accompanied by a Clarendon Homes construction team member.

A visitor induction is to include a verbal explanation of the following points:

- Emergency Assembly Point,

- Location of amenities;

- PPE requirements;

- How to report a hazard or incidents that are identified or occurred onsite;

- Any other hazards that requires mention

|

Whom |

OHS Construction Induction |

Work Place or task specific / Training |

Clarendon HSE Contractor Induction |

Visitor Induction |

|

|

|

|

|

X |

|

Contractors |

X | X | X |

|

|

Construction Staff |

X | X | X |

|

|

Clarendon Employees |

|

|

|

X |

Hazard & Risk Management

Risk Assessment

Pre-Start

A Pre-Start Site Specific Risk Assessment is competed prior to establishing a site presence and once we have been granted access to the site. This risk assessment assesses the risks relating to:

- site services,

- overhead powerlines,

- environmental requirements,

- traffic,

- site access,

- waste,

- excavation, etc.

Hazards and control measures will be communicated by using the following methods:

- Site Plans

- Site Safety Signage

- Direct or telephone contact

Control of Risk

Control measures are to be implemented to eliminate the risk wherever possible or reduce the risk to its lowest level. Measures to control hazards are to be implemented in accordance with the following hierarchy of control. The control measures at Level 1 give the best result and should be adopted wherever possible. The measures at the lower levels are less effective and they require more frequent reviews of the hazards and systems of work. In some situations a combination of control measures may need to be considered.

Hierarchy of Control

The following hierarchy of control measures are listed below. Select from the lowest number level possible.

Level 1: Eliminate the risk (e.g. discontinue the activity or remove the hazard altogether)

Level 2: Minimise the risk by: -

- substituting the system of work or plant (with something safer)

- modifying the system of work or plant (to make it safer)

- isolating the hazard (e.g. introduce restrictive work area)

- introducing engineering control (e.g. guarding, fencing

Level 3: Other controls: - adopting administrative controls and safe work practices (e.g. specific instructions)

- using PPE (e.g. eye protection, hard hats)

Safe Work Method Statements (SWMS)

High Risk Construction Activities

All contractors who undertake high risk construction activities are required to submit their SWMS for review prior to commencing work onsite and every 2 years thereafter. The SWMS will be reviewed using the Clarendon Group “Standards for high risk construction activities” on all Clarendon Sites.

The review will have 2 possible outcomes:

- SWMS is reviewed and accepted or

- SWMS is reviewed and rejected.

SWMS should be developed or amended in consultation with your employees and subcontractors performing the task to ensure that it is up to date with your current work practices. It is also equally important that all your sub contracted workers are also trained in the implementation of the SWMS. A copy of the contractors SWMS will be retained by Clarendon and must be available on site at all times by the contractor.

Clarendon Homes may also provide a sample SWMS to assist contactors in developing their own SWMS or alternatively contractors may adopt the sample SWMS if it accurately reflects their work practices.

Clarendon Homes will periodically monitor contractors using Clarendon Homes Contractor Audit checklist to ensure that they are performing work in line with their approved SWMS and Clarendon Site Safety Rules. Any non-conformances will be dealt with using the Contractor Non Performance Process.

Non High Risk Construction Activates

Contractors who do not undertake high risk construction activities will only need to demonstrate that they have basic procedures in place for their work activity and that they have trained there workers in these procedures. Typical examples include: SWMS, JSA’s, Toolbox Talk records and Safe Work Procedures.

The Site Manager and HSE Department will periodically monitor contractor’s compliance through site inspections and evaluating contractor’s compliance to their SWMS.

Contractors Site Specific Risk Assessments (SSRA)

All contractors are required to undertake a Site Specific Risk Assessment prior to starting work on site and all hazards and controls must be documented on the SSRA form. All workers including the Clarendon Site Manager must be notified of the hazards that have been identified and control measures that will be implemented. The complete or partially completed Risk Assessment form must be readily available on site at all time.

If a high risk construction activity is required to be undertaken and is not documented in the contractors SWMS then the Contractor must refer to page 10 “Standards for high risk construction activities” of this WHS Management Plan to determine the specific control measures that need to be implemented for the high risk construction activity about to be undertaken. This must also be documented on the contractors SWMS or SSRA form.

Working Alone

If you plan to work alone on a Clarendon Construction Site and the work is a “high risk construction activity” e.g. working at heights, you must contact the Clarendon Site Manager and provide a start / finish time and contact details (home and mobile).

WHS Communication And Consultation

Consultation is crucial to enable you and everyone onsite to contribute to decision making that affects the health, safety and welfare of everyone working onsite.

Contractors

Contractors are required to actively participate in any consultation and communication that occurs on site.

Clarendon will use the following methods for site communication and consultation:

- Toolbox Meetings

- Safety Alerts

- Training Sessions

- Site Signage

- Site Plans

Clarendon Homes will periodically undertake toolbox meetings with their contractors to ensure that and workplace issues or changes are effectively communicated. This may include but not limited too : risk assessments, site trials and process or legislative changes.

All toolbox meetings held onsite involving contractors will be minuted and an attendance list will be generated. Contractors can demonstrate consultation by conducting toolbox meetings with their workers. It is expected that these meetings are minuted and a copy made available for the Site Manager’s verification and distribution.

WHS Issue Resolution

WHS Issue Resolution

The normal process for resolution of a WHS issue is to address it at a site level wherever possible and only escalate issues to higher management levels where required. Where an issue is identified that cannot be resolved by site personnel, the Clarendon Site Manager or Construction Area Manager (CAM) is to be contacted. If the Site Manager or CAM cannot resolve the issue, Clarendon HSE Management will be contacted to assist in resolving the issue.

Contractors are expected to bring WHS issues that arise in the course of the work to the attention of the Clarendon Site Manager. If it is possible for the contractor to fix the problem they are expected to do so. Issues can be documented on the Clarendon Incident Report Form or Contractor Site Specific Risk Assessment and can be given to either the Site Manager, CAM or send to the HSE Department at [email protected] or Fax: 02 9841 0251.

Emergency Procedures

In the event of an emergency situation onsite the following steps should be followed:

- Recover or protect injured persons ONLY if it is safe to do so.

- Immediately alert all other contractors in the area of danger.

- Proceed to the front gate or the nearest point of safety

- Ensure all persons are accounted for.

- Contact emergency services if required. (refer to Site Safety Sign)

- Notify the Site Manager IMMEDIATELY

- Do not leave site until instructed by the Site Manager

NOTE: If the Site Manager cannot be contacted, then contact the Emergency Contact Number.

Incident Management

All accidents, incidents and/or near misses that occur onsite must be reported to the Clarendon Homes Site Manager. In the event it involves a contractor, it is an expectation that the affected contractor will record all details using their own reporting tool and a copy is to be provided to the Site Manager. In the event an incident involves a visitor to the site, the Clarendon Homes Incident Report Form will need to be completed

NOTE: If the Site Manager is not contactable, contact the CAM or the Emergency Contact Number displayed on the site details sign located on the front security fence.

Notifiable Incidents

All Notifiable incidents must be immediately reported to the Clarendon Site Manager or Emergency Contact.

In the event of a Notifiable incident (as listed below) a SCENE OF NON-DISTURBANCE must be established and must not be disturbed in any way unless to assist an injured person or make the area safe. Non-disturbance period applies until directed by a regulatory inspector.

A Notifiable incident includes incidents with the following types of outcomes:

- the death of a person, or

- a serious injury or illness of a person, or

- a dangerous incident.

Serious Incident

In this Part, serious injury or illness of a person means an injury or illness requiring the person to have:

- immediate treatment as an in-patient in a hospital, or

- immediate treatment for:

- the amputation of any part of his or her body, or

- a serious head injury, or

- a serious eye injury, or

- a serious burn, or

- the separation of his or her skin from an underlying tissue (such as de-gloving or scalping), or

- a spinal injury, or

- the loss of a bodily function, or

- serious lacerations, or

- medical treatment within 48 hours of exposure to a substance, and includes any other injury or illness prescribed by the regulations but does not include an illness or injury of a prescribed kind.

Dangerous incident

In this Part, a dangerous incident means an incident in relation to a workplace that exposes a worker or any other person to a serious risk to a person’s health or safety emanating from an immediate or imminent exposure to:

- an uncontrolled escape, spillage or leakage of a substance, or

- an uncontrolled implosion, explosion or fire, or

- an uncontrolled escape of gas or steam, or

- an uncontrolled escape of a pressurised substance, or

- electric shock, or

- the fall or release from a height of any plant, substance or thing, or

- the collapse, overturning, failure or malfunction of, or damage to, any plant that is required to be authorised for use in accordance with the regulations, or

- the collapse or partial collapse of a structure, or

- the collapse or failure of an excavation or of any shoring supporting an excavation, or

- the inrush of water, mud or gas in workings, in an underground excavation or tunnel, or

- the interruption of the main system of ventilation in an underground excavation or tunnel, or

- any other event prescribed by the regulations, but does not include an incident of a prescribed kind.

Contactor Non Conformances

Contractors failing to perform their work activity in line with the requirement set out in state legislation, Clarendon Site Safety Plan and the Contractors SWMS or Risk Assessment will be dealt with in the following fashion.

Verbal Notification

Any minor infringement that creates minimal risk to health and safety and can be rectified immediately via verbal or disciplinary instructions (phone or otherwise) and recorded in the Site Managers Diary.

Site Instruction or Opportunity for Improvement Notice

This notice is issued when a contractor commits a direct breach or contravention of WHS legislation, Clarendon HSE Policy / Procedures or the WHS Management Plan. The Site Instruction or Opportunity for Improvement Notice may be issued directly to a contractor or supplier by a HSE Manager.

If a contractor or supplier is not present on site at the time, then the Site Manager will contact the offending contractor and/or supplier and notify them of their breach or safety issue. The notice will then be mailed or faxed to the offending contractor or supplier. Once closed out, Site Instructions or Opportunity for Improvement Notices will be stored on record in the contractors file.

Stop Work Instruction

A “Stop Work Instruction” MUST be issued when a risk, hazard or dangerous work practice has been identified and has the likelihood of causing serious injury or death.

If a contractor or supplier is not present on site at the time, then the Site Manager must call the contractor and/or supplier notifying them of “Stop Work Instruction” and document the call in site diary. Work will not resume until such times that the Site Manager or HSE Manager is satisfied that the Safe Work Method Statement or legislative requirements have been complied with.

Where necessary, the following temporary control measures must be undertaken to prevent in authorised access and to raise general awareness of the identified risk or hazard.

- Physical barrier/ barricade

- Danger signage (i.e. Scaffold Incomplete, Electrical hazard in vicinity )

- Danger tape

Breach Notice

Breach notices is a first and final notice that are issued to contractors and suppliers for majors safety breaches and non conformances , such as working at heights , unsafe work practices , repeated non conformance , a worker placing their own and other lives in danger.

The recipient of a breach notice much reply in writing about how there organisation will prevent further safety breaches and non conformances from occurring.

Further conformance or failing to meet the terms of the breach notice will result in the cancelation of the business contract with Clarendon.

Cancellation of Business Contract

All notices are registered on a centralised database which is reviewed on a periodic basis. Contractors who consistently breach safety requirements may have their business contract cancelled and be removed from the Approved Contractor List.

Environmental Management

Asbestos

Clarendon Homes does not use materials that contain asbestos on its sites. At times (e.g. after a demolition), some materials suspected to contain asbestos may be found on a site.

If material is encountered that is suspected to be asbestos:

- Stop work

- Do not disturb the material.

- Move your self and others away from the contaminated area

- Contact the Clarendon Site Manager who will arrange for an appropriately qualified and licensed contractor to identify and remove the material.

If there is asbestos contamination on site, an Asbestos Clearance certificate will obtained before work on site will recommence.

Sediment and Erosion control

Sediment fence and erosion are used on Clarendon site to prevent debris and runoff entering drains .storm water, creek , water coarse or neighbouring properties .Contactor and supplier must make every effort to protect and preserve the sediment and erosion control on site. If a sediment control barrier has been knocked over or removed it must be immediately reinstated before commencing work. Please contact the Site Manager immediately if any sediment or erosion controls require rectification.

Paint wash out

Run of from construction activities such as using a brick saw , washing painting or concreting equipment must never leave the site and must never enter a drains ,storm water, creeks, water coarse or neighbouring properties. Any run off should be bunded or directed into a filtration barrier on site.

Debris on roads

Any debris or mud tracked onto the adjacent roads or footpaths for a vehicle entering or exiting a Clarendon site must be clean up immediately by the driver. If the waste cannot be clean off the road then the Clarendon Site Manager must be notified immediately so that further arrangements can be made for cleaning. Failure to clean up any mud and debris will result in back charges.

Hazardous Chemicals

All hazardous chemicals used on a Clarendon site must be register in the contractor hazardous chemical register and have safety data sheet available on site at all times.

All hazardous chemical must be removed from site each day and not stored on site over night.

Minor Chemical Spills

Contractors are required to clean up minor chemical skills using an appropriate (portable) Emergency Spill Kit. Waste shall be disposed in accordance with local council regulations.

Major Chemical Spill

In the event of an emergency which could have a significant impact on the environment (i.e. large spill of hazardous chemicals or dangerous goods) the following actions should be taken:

- Wherever possible contain the spill or leak. Contact the Site Manager who will determine if the leak or spill can be clean up using a spill kit, etc.

- If the leak or spill is major and cannot be contained contact the NSW Fire Brigade and EPA 131 555. State the Hazchem code from the MSDS.

Standard Controls For High Risk Construction Activities

The document has been produced to assist you in developing your Safe Work Methods and also to highlight WHS responsibilities with respect to high risk construction activities.

To help you determine what “high risk activity” is applicable to you and your business, please complete the simple questionnaire below.

If you answer “Yes” to any of the questions below, go to the nominated page (12 to 33), identify your trade responsibilities then update your Safe Work Method Statement to include the trade’s control measures shown.

|

QUESTION |

NO |

YES |

|

|

....... |

....... |

If yes , refer to page 12 |

|

....... |

....... |

If yes , refer to page 13 |

|

....... |

....... |

If yes , refer to page 14 |

|

....... |

....... |

If yes , refer to page 15 |

|

....... |

....... |

If yes , refer to pages 16 |

|

....... |

....... |

If yes , refer to pages 17 |

|

....... |

....... |

If yes , refer to pages 18 |

|

....... |

....... |

If yes , refer to pages 19 |

|

....... |

....... |

If yes , refer to pages 20 |

|

....... |

....... |

If yes , refer to pages 21 |

|

....... |

....... |

If yes , refer to pages 22 |

|

....... |

....... |

If yes , refer to pages 23 |

|

....... |

....... |

If yes , refer to pages 24 |

|

....... |

....... |

If yes , refer to pages 25 |

|

....... |

....... |

If yes , refer to pages 26 |

|

....... |

....... |

If yes , refer to pages 27 |

|

....... |

....... |

If yes , refer to pages 27 |

|

....... |

....... |

If yes , refer to pages 29 |

|

....... |

....... |

If yes , refer to pages 31 |

|

....... |

....... |

If yes , refer to pages 32 |

| Work carried out near energised electrical installations or services.

Underground electrical |

||||

|

Clarendon responsibilities |

Controls measures |

|||

|

|

|

|||

|

Trades responsibilities |

Trade’s control measures Your SWMS should mention the items below: |

|||

|

|

|

|||

|

Work carried out near energised electrical installations or services. Overhead Powerlines - Powered Mobile Plant |

||||

|

Clarendon responsibilities |

Clarendon control measures |

|||

|

|

|

|||

|

Trades responsibilities |

Trade’s control measures Your SWMS should mention the items below: |

|||

|

|

Your SWMS should mention the items below: Minimum ordinary persons approach distances 3 metres – up to 132,000 volts 6 metres – 132,000 to 330,000 volts 8 metres – above 330,000 volts

Workers to wear PPE (rubber soled shoes, anti-static gloves and use non-conductive hand tools) Do not commence work if the applicable safe approach distances cannot be maintained. |

|||

|

Work carried out near energised electrical installations or services. Overhead Powerlines – Scaffold supply and install |

|

|

Clarendon responsibilities |

Clarendon control measures |

|

|

Minimum approach distances for ordinary persons: 3 metres – up to 132,000 volts

|

|

Trades responsibilities |

Trade’s control measures Your SWMS should mention the items below: |

|

|

|

Work carried out near gas distribution mains Underground Gas |

||||

|

Clarendon responsibilities |

Clarendon control measures |

|||

|

|

|

|||

|

Trades responsibilities |

Trade’s control measures Your SWMS should mention the items below: |

|||

|

|

|

|||

|

Falls from Heights greater than 2 metres Installation of 1st floor flooring and frames |

||||

|

Clarendon responsibilities |

Clarendon control measures |

|||

|

|

|

|||

|

Trades responsibilities |

Trade’s control measures Your SWMS should mention the items below: |

|||

|

|

|||

|

Falls from Heights greater than 2 metres Truss installation |

||||

|

Clarendon responsibilities |

Clarendon control measures |

|||

|

|

|

|||

|

Trades responsibilities |

Trade’s control measures Your SWMS should mention the items below: |

|||

|

|

|||

|

Falls from Heights greater than 2 metres Working in the roof cavity |

|

|

Clarendon responsibilities |

Clarendon control measures |

|

|

|

|

Our Contractors responsibilities |

Trade’s control measures Your SWMS should mention the items below: |

|

|

|

Falls from Heights greater than 2 metres Exterior work to the front and side elevations |

|

|

Clarendon responsibilities |

Clarendon control measures |

|

|

|

|

Our Contractors responsibilities |

Trade’s control measures Your SWMS should mention the items below: |

|

|

|

Falls from Heights greater than 2 metres Roof work |

|

|

Clarendon responsibilities |

Clarendon control measures |

|

|

|

|

Our Contractors responsibilities |

Trade’s control measures Your SWMS should mention the items below: |

|

|

|

Falls from Heights greater than 2 metres Plasterboard Delivery |

||||

|

Clarendon responsibilities |

Clarendon control measures |

|||

|

|

|

|||

|

Our Contractors responsibilities |

Trade’s control measures Your SWMS should mention the items below: |

|||

|

|

Stair void delivery:

External balcony pass up:

|

|||

|

Falls from Heights greater than 2 metres Using extension ladders |

|

|

Our Contractors responsibilities |

Trade’s control measures Your SWMS should mention the items below: |

|

When using an extension ladder:

|

|

Work carried out in a workplace in which there is any movement of powered mobile plant |

||

|

Clarendon responsibilities |

Clarendon control measures |

|

|

|

Communicate and coordinate traffic control for specific deliveries or powered mobile plant movements on site. |

|

|

Our Contractors responsibilities |

Trade’s control measures Your SWMS should mention the items below: |

|

|

|

|

|

Work Carried out adjacent to a road or other traffic corridor that is used by traffic or other pedestrians |

||

|

Clarendon responsibilities |

Clarendon control measures |

|

|

|

Communicate and coordinate traffic control for specific deliveries or powered mobile plant movements on site. |

|

|

Our Contractors responsibilities |

Trade’s control measures Your SWMS should mention the items below: |

|

|

|

|

|

Work carried out, in or near an excavation or trench greater then 1.5 metres in depth |

|

|

Clarendon responsibilities |

Clarendon control measures |

|

|

|

|

Our Contractors responsibilities |

Trade’s control measures Your SWMS should mention the items below: |

|

|

|

Work carried out in an area that may have a contaminated or flammable atmosphere Cutting or grinding concrete ,bricks , concrete blocks and pavers containing crystalline silica |

|

|

Clarendon responsibilities |

Clarendon’s control measures |

|

|

|

|

Our Contractors responsibilities |

Trade’s control measures Your SWMS should mention the items below: |

|

|

|

Work carried out in an area that may have a contaminated or flammable atmosphere Cutting or composite stone bench tops that contain crystalline silica |

|

|

Clarendon responsibilities |

Clarendon’s control measures |

|

|

|

|

Our Contractors responsibilities |

Trade’s control measures Your SWMS should mention the items below: |

|

Bench Top installers – no cutting on site

|

The cutting of stone bench tops is a prohibited activity on all Clarendon and Domaine Homes construction sites. |

|

Work carried out in an area that may have a contaminated or flammable atmosphere Cutting Hebel products that contain crystalline silica |

|

|

Clarendon responsibilities |

Clarendon’s control measures |

|

|

|

|

Our Contractors responsibilities |

Trade’s control measures Your SWMS should mention the items below: |

|

|

|

Work carried out in an area that may have a contaminated or flammable atmosphere Cutting floor and wall tiles that contain crystalline silica |

|

|

Clarendon responsibilities |

Clarendon’s control measures |

|

|

|

|

Our Contractors responsibilities |

Trade’s control measures Your SWMS should mention the items below: |

|

Below are three tile cutting methods ranging from best and most preferred to least effective method for the control of crystalline silica dust when cutting tiles: Best methods to control silica dust

When cutting the operator must implement the following safety controls:

|

|

Work carried out in an area that may have a contaminated or flammable atmosphere Mixing adhesives , render or grouts that crystalline silica |

||

|

Clarendon responsibilities |

Clarendon’s control measures |

|

|

|

|

|

|

Our Contractors responsibilities |

Trade’s control measures Your SWMS should mention the items below: |

|

|

|

|

|

Work carried out in an area that may have a contaminated or flammable atmosphere Cutting , drilling , grinding and sanding fibre cement products that contain crystalline silica |

|

|

Clarendon responsibilities |

Clarendon’s control measures |

|

|

|

|

Our Contractors responsibilities |

Trade’s control measures Your SWMS should mention the items below: |

|

|

Respirable Silica Dust Control Plan

Details of Products Containing Respirable Silica

|

Trade type affected by product |

Product |

Silica Content |

SDS Hyperlink |

|

Concreter

Framing Carpenter

Plumber |

Boral Ready Mix Concrete

Holcim Concrete |

30%-60%

20% |

https://www.boral.com.au/sites/default/files/media/field_document/BORAL%20PRE-MIXED%20CONCRETE_0.pdf https://www.holcim.com.au/sites/australia/files/documents/holcim-premixedconcrete-sds.pdf?v=a7cdf563

|

|

Bricklayer

Plumber |

Austral Bricks

PGH Bricks

|

up to 60%

up to 60% |

|

|

Framing Carpenter

Eaves and Cladding Carpenter |

James Hardie Fibre Cement Products |

10%-60% |

|

|

Hebel installer

Plumber |

Hebel – Autoclaved Aerated Concrete

Hebel – Adhesive |

20% - 40%

<60% |

https://hebel.com.au/wp-content/uploads/2022/Hebel-Silica-Fact-Sheet-and-SDS.pdf

https://hebel.com.au/wp-content/uploads/2022/SDS-Hebel-Adhesive.pdf

|

|

Roof tiler |

Bristile

Lutum

Monier

|

50% - 70%

Greater than 60% 10% to 70%

Greater than 80%

Greater than 40%

|

https://www.lutum.com.au/_files/ugd/a92fab_f559ced65a084b88a51ba0b873ec30fc.pdf https://www.lutum.com.au/_files/ugd/a92fab_1bab639dc9144930be08424f60ddf7ce.pdf

|

|

Benchtop manufacture – prohibited to be cut on site |

Quantum Quartz

|

Greater than 88% |

https://www.wk.com.au/Files/Files/QQ%20SDS.pdf

|

|

Floor and wall tiler

Plumber

Electrician |

Floor and wall Tiles

|

5% to 45% 60% to 70% |

Information obtained from website - unable to source SDS

Beaumont Tiles – safe cutting instructions https://www.beaumont-tiles.com.au/blogs/cutting#smallshapes

|

Controlling the Risk of Exposure to Respirable Silica

Note: Areas highlighted in yellow identify when RPE is a mandatory requirement

| Place | Task | Control Measures | Respiratory Protection | Work Practices | How controls are integrated into daily activities |

| Outdoors & indoors / enclosed areas |

Handheld grinder used for grinding or cutting concrete slabs (small areas) |

Equipped with integrated water delivery system that continuously feeds water to the cutting surface. |

Equipped with integrated water delivery system that continuously feeds water to the cutting surface. |

Ensure:

|

Prestart inspection / check of tool and daily cleaning of work areas.

|

| Outdoors |

Handheld grinder used for grinding or cutting concrete slabs (small areas) |

Tool be fitted with commercially available shroud and M or H class dust collection system. Dust collector must:

|

Outdoor – None Addition safety precaution operator can wear P1 or P2 respirator / mask. This will not count towards your 30 day trigger for health monitoring. |

Ensure:

Dust extractor

|

Prestart inspection / check of tool and daily cleaning of work areas.

|

| Indoors / enclosed areas |

Handheld grinder used for grinding or cutting concrete slabs (small areas) |

Tool be fitted with commercially available shroud and M or H class dust collection system. Dust collector must:

|

Operating for less than 4 hours – no RPE Operating for more than 4 hours per shift then the operator must wear a P1 or P2 respirator / mask .Operator must have mask fit tested. PCBU to provide health monitoring, if worker has undertaken tasks requiring RPE for 30+ days in 12 months. |

Ensure:

|

Prestart inspection / check of tool and daily cleaning of work areas.

|

| Outdoors | Walk behind concrete grinder |

Equipped with integrated water delivery system that continuously feeds water to the cutting surface. Or Tool be fitted with M or H class dust collection system. Operate and maintain tool in accordance with manufactures instructions to minimise dust emissions When indoors or in an enclosed areas use either an M or H class vacuum to remove loose dust in between passes. |

Outdoor – None Addition safety precaution operator can wear P1 or P2 respirator / mask. This will not count towards your 30 day trigger for health monitoring |

Ensure:

Or

|

Prestart inspection / check of tool and daily cleaning of work areas.

|

|

Outdoor & Indoors / enclosed area |

Hand drill used to drill holes in slab / brick / Hebel panels or floor and wall tiles |

Operate and maintain tool in accordance with manufactures instructions to minimise dust emissions Use tool with on tool dust collection system. Dust collector must provide the air flow recommended by the tool manufacturer, or greater, and have either:

|

Outdoor – None Addition safety precaution operator can wear P1 or P2 respirator / mask. This will not count towards your 30 day trigger for health monitoring |

Ensure:

|

Prestart inspection / check of tool and daily cleaning of work areas.

|

|

Outdoor & Indoors / enclosed area |

Stationary brick saw or tile saw |

Integrated water delivery system that feeds water to the blade Operate and maintain tool in accordance with manufactures instructions to minimise dust emissions |

Outdoor – None |

Ensure:

|

Tool box talks, pre-start checks and daily cleaning of work areas. E.g. daily checks:

|

|

Outdoor & Indoors / enclosed area |

Stationary brick saw or tile saw |

Use a saw with either:

|

Operating must wear a P1 or P2 respirator / mask. Operator must have mask fit tested PCBU to provide health monitoring, if worker has undertaken tasks requiring RPE for 30+ days in 12 months. |

Ensure:

|

Prestart inspection / check of tool and daily cleaning of work areas.

|

| Outdoors | Handheld power saw or drop saw to cut fibre cement products |

Use saw equipped with commercially available dust collection system; and Equipped with “Hardieblade” Operate and maintain tool in accordance with manufacturer's instructions to minimise dust emissions; and Dust collector must provide the air flow recommended by the tool manufacturer, or greater, and be rated to either M or H-Class in accordance with AS/NZS 60335.2.69. |

Outdoor – None Addition safety precaution operator can wear P1 or P2 respirator / mask This will not count towards your 30 day trigger for health monitoring |

Ensure:

|

Prestart inspection / check of tool and daily cleaning of work areas.

|

| Outdoors | Handheld power saw to cut Hebel |

Use saw equipped with commercially available dust collection system; and Operate and maintain tool in accordance with manufacturer's instructions to minimise dust emissions; and Dust collector must provide the air flow recommended by the tool manufacturer, or greater, and be rated to either M or H-Class in accordance with AS/NZS 60335.2.69. |

Outdoor Operator must wear a P1 or P2 respirator / mask. Operator must have mask fit tested PCBU to provide health monitoring, if worker has undertaken tasks requiring RPE for 30+ days in 12 months. |

Ensure:

|

Prestart inspection / check of tool and daily cleaning of work areas.

|

| Outdoors / enclosed area | Handheld grinder used to cut / trim wall and floor tiles |

Use grinder equipped with commercially available dust collection system; and Operate and maintain tool in accordance with manufacturer's instructions to minimise dust emissions; and Dust collector must provide the air flow recommended by the tool manufacturer, or greater, and be rated to either M or H-Class in accordance with AS/NZS 60335.2.69. Have a cyclonic pre-separator or filter cleaning mechanism |

Outdoor – None Addition safety precaution operator can wear P1 or P2 respirator / mask. This will not count towards your 30-day trigger for health monitoring Indoors or enclosed areas Operating for more than 4 hours per shift then the operator must wear a P1 or P2 respirator / mask .Operator must have mask fit tested PCBU to provide health monitoring, if worker has undertaken tasks requiring RPE for 30+ days in 12 months. |

Ensure:

|

Must be done outside (garage or alfresco) in a well-ventilated area. Close all doors to the house where possible to prevent dust contamination. Prestart inspection / check of tool and daily cleaning of work areas.

|

| Outdoors | Handheld grinder used to cut / trim wall and floor tiles |

When cutting the operator must implement the following safety controls: Must be done outside (garage or alfresco) in a well-ventilated area. Close all doors to the house where possible to prevent dust contamination. Person cutting or grinding must wear a P1 or P2 half face respirator during cutting and fitted in accordance with the manufacture’s recommendations |

Operator must wear a P1 or P2 respirator / mask. Operator must have mask fit tested PCBU to provide health monitoring, if worker has undertaken tasks requiring RPE for 30+ days in 12 months. |

Cutting blade” is maintained to ensure cutting efficiency and minumise dust emissions Clean grinding area by wet sweeping area– never dry sweep or blow tile dust. Bag slurry / dust and dispose of in waste enclosure |

Ensure:

|

| Outdoors/ house not enclosed | Wet sweep - Cleanup / Housekeeping | Ensure sufficient water is added to the work area to prevent elevated airborne dust |

Outdoor – None Addition safety precaution operator can wear P1 or P2 respirator / mask. This will not count towards your 30 day trigger for health monitoring |

Bag slurry / dust and dispose of in waste enclosure | Ensure that there is adequate water supply to wet work area |

| Outdoors/ house not enclosed |

Cleanup / Housekeeping Dry sweep |

Isolate work area Person sweeping must wear a P1 or P2 half face respirator during sweeping and fitted in accordance with the manufacture’s recommendations |

Operator must wear a P1 or P2 respirator / mask. Operator must have mask fit tested PCBU to provide health monitoring, if worker has undertaken tasks requiring RPE for 30+ days in 12 months. |

Notify other workers that sweeping is about to commence Bag waste and dispose of in waste enclosure |

Ensure:

|

| Indoor |

Cleanup / Housekeeping Dry sweep |

Isolate work area Person sweeping must wear a P1 or P2 half face respirator during sweeping and fitted in accordance with the manufacture’s recommendations |

Operator must wear a P1 or P2 respirator / mask. Operator must have mask fit tested PCBU to provide health monitoring, if worker has undertaken tasks requiring RPE for 30+ days in 12 months. |

Notify other workers that sweeping is about to commence Bag waste and dispose of in waste enclosure |

Ensure:

|

| Indoor |

Cleanup / Housekeeping Vacuum |

Use either a M or H class vacuum cleaner | Indoor – None |

|

Ensure

|

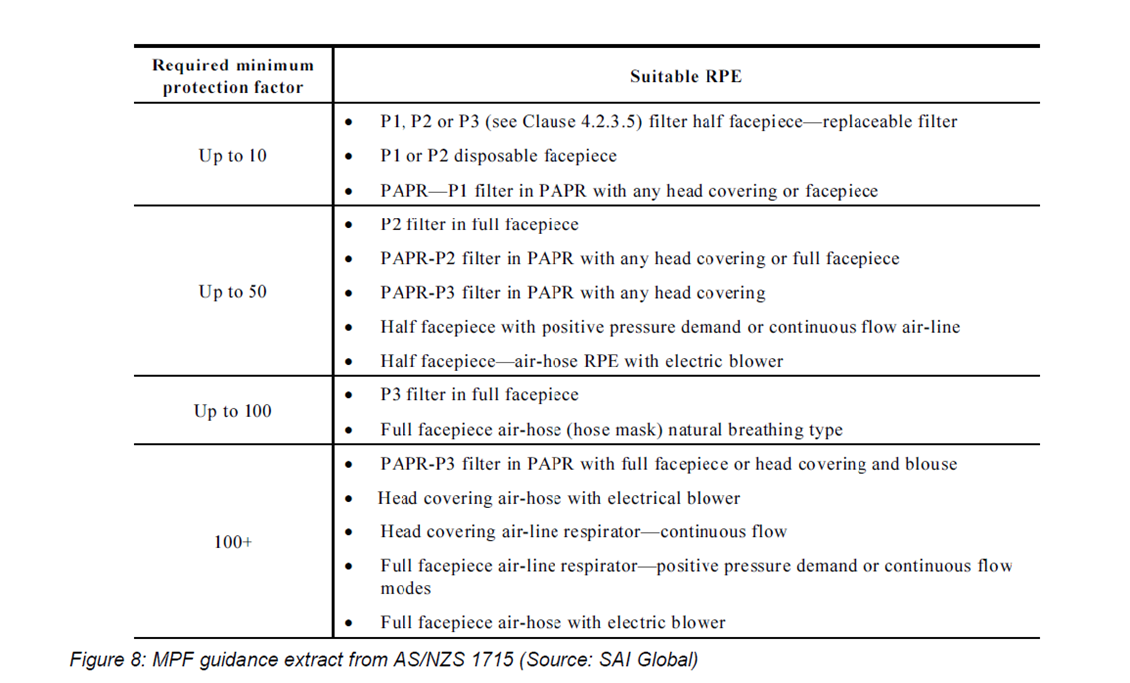

Choosing the right RPE

When choosing the RPE, you must consider the worker who will be using the RPE;

- Workers may have pre-existing medical conditions (for example, chronic lung diseases such as asthma) that could restrict or prevent the wearing of certain types of respirators.

- Comfort: face shape and size will influence the size and model of respirator appropriate for each wearer.

- Facial hair. This can be an issue for tight-fitting respirators (i.e., half and full-face RPE, both negative and positive pressure) because the hair can prevent it from forming a tight fit.

When choosing the RPE, you must consider the task the RPE will be used for;

- How long does the RPE need to be worn and the physical demands of the task for example, wearing unpowered RPE for more than an hour or during hard physical work may become uncomfortable and result in a person removing the respirator while still in a contaminated area.

- What other PPE will be worn. For example, some safety glasses may interfere with the fit of the respirator.

- Whether the task requires the worker to have unrestricted vision or be able to speak clearly.

When choosing the RPE, you must consider the work environment

- How hot and humid the work environment is. For example, powered respirators may be more appropriate where heat stress is a risk.

Fit-testing

Fit-testing is required for all tight-fitting RPE provided by the PCBU to protect against RCS.

Fit-testing detects if air leaks into the respirator through gaps in the seal between the respirator facepiece and face. It is an essential step in the RPE selection process and allows a PCBU to determine if the specific make and model of RPE is a suitable size, fit and comfort for the worker who is going to use it.

Fit-testing must be undertaken before the specific make and model of RPE can be used. Planning fit-testing should form part of the review process for producing a Safe Work Method Statement or an RCS Dust Control Plan.

Frequency of fit-testing

In addition to ensuring a tight-fitting respirator has been successfully fit-tested before it is first used, fit-testing should also occur:

- at least once per year

- whenever there is a change in the wearer's facial characteristics or features which may affect the facial seal (e.g. large weight loss or gain).

- each time a new make or model of tight-fitting respirator is issued.

Fit-testing can be carried out by any competent person who meets the above requirements, including but not limited to a manufacturer, supplier or service provider.

Training for workers who use RPE

When issuing RPE, training must be provided to ensure that workers correctly use and maintain RPE. Initial training is best delivered when undertaking the fit-testing of RPE with workers. Training should be provided by a competent person,